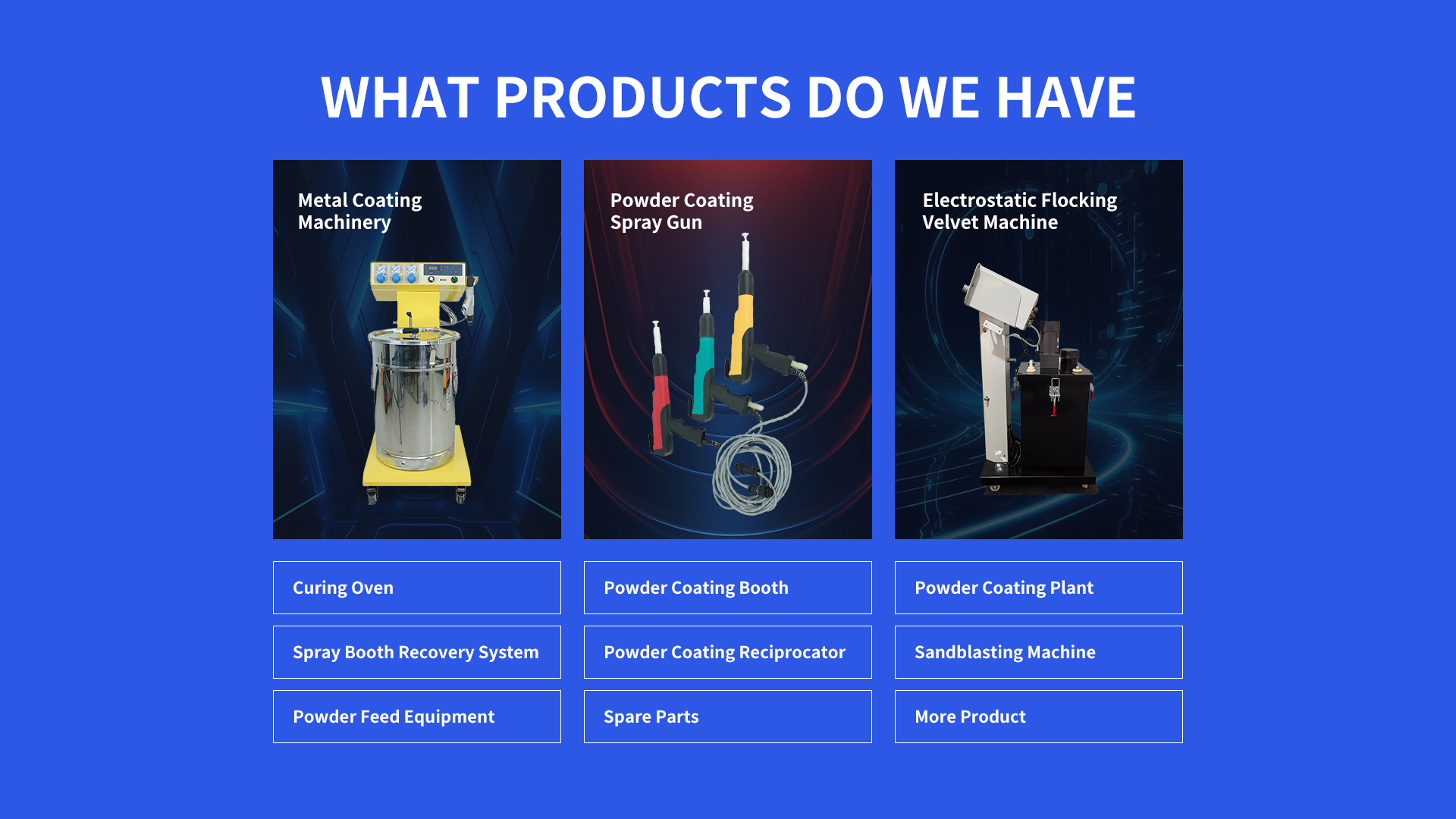

1. Introduction and Structure of Powder Coating EquipmentPowder Coating Equipment is key for quality surface finishes. It mainly consists of a powder coating booth with spray guns (manual or automatic) for applying powder. The curing oven, featuring precise temperature control, fuses the powder. A conveyor moves workpieces through the process, and a powder recovery system cuts down on waste. A control panel manages the whole operation.

2. Application Scenarios of Powder Coating Equipment

This equipment is in high demand across industries. In automotive, it coats car parts for protection and looks. Metal furniture makers use it to give their products a durable, nice finish. For electronics, it coats device casings, providing protection and a modern appearance.

3. Prices of Powder Coating EquipmentPowder Coating Equipment prices vary widely. Basic setups for small-scale use or DIY start at around $10,000. Mid-range gear with better features like higher powder transfer and stable oven temps costs between $20,000 and $50,000. High-end, fully automated systems for large production can go over $50,000.

4. Correct Usage Method of Powder Coating Equipment

First, clean and degrease workpieces. Load them onto the conveyor if there is one. Adjust spray gun settings according to the powder and workpiece. Preheat the oven to the right temp. Start coating and keep an eye on the process, making changes as needed. After coating, cure the workpieces and then cool them.

5. How to Select Powder Coating EquipmentWhen picking

Powder Coating Equipment, think about your production volume. For lots of production, automated systems are great. Check the quality of spray guns, the efficiency of the powder recovery, and the oven's temperature accuracy. Consider the manufacturer's reputation and after-sales support. Also, match it to your budget.

6. Safety Precautions of Powder Coating Equipment

Safety matters when using this equipment. Workers should wear protective gear like respirators, gloves, and goggles to avoid powder inhalation and protect skin and eyes. Ensure good ventilation in the booth to prevent powder dust buildup. Regularly check electrical and mechanical parts for problems.

7. Rationality Analysis of Powder Coating EquipmentInvesting in

Powder Coating Equipment makes sense. It boosts efficiency, cuts labor costs, and ensures consistent quality. The powder recovery system saves money on powder, and in-house coating gives you more control over production.

8. Q&A about Powder Coating Equipment

Q1: Can powder coating equipment handle different powder types?

A: Yes, but clean the equipment thoroughly between different powders to avoid mixing.

Q2: How often should I service the curing oven of powder coating equipment?

A: Inspect it monthly for heating elements and sensors. Do a full cleaning and maintenance every six months.

Q3: What's so great about high-end powder coating equipment?

A: High-end gear offers better precision, faster speeds, advanced controls, and longer life, improving production and quality.

Q4: Is installing powder coating equipment a tough job?

A: It depends. Small, basic systems are easier, while large, automated ones may need professional help.

Q5: How does the powder recovery system of powder coating equipment work?

A: It uses filters or cyclones to separate powder from the air in the booth. The collected powder can be reused, reducing waste.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com